Company Adds Talent in Purchasing, Compliance and Office Management

Mack Prototype President Greg Cebular shows off a large part from the Company’s new Stratasys F770 3D Printer.

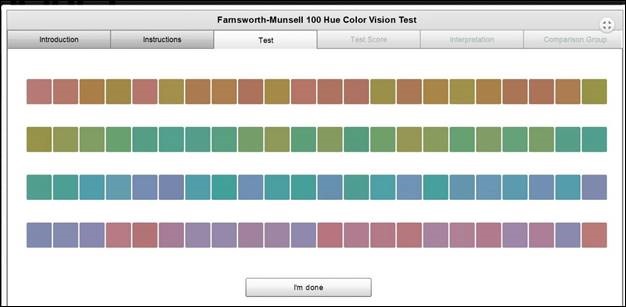

GARDNER, Mass. (Feb. 7, 2023) – Mack Prototype, a wholly-owned subsidiary of Mack Molding Co. focused on complex prototyping and low-volume manufacturing, has grown its additive manufacturing capabilities with the addition of a Stratasys F770 capable of producing large 3D printed parts.

The F770 is a Fused Deposition Modeling (FDM) system that runs both ABS and ASA materials. It features the widest build chamber of any Stratasys FDM 3D printer and a significant build envelope that spans 39 inches by 24 inches by 24 inches. That is 13-cubic feet of build volume allowing it to produce large parts or significant assortments of smaller parts. Typical part accuracy is +/- .010 inches (.254 millimeters) or +/- .002 inches/inches (.050 millimeters/millimeters), whichever is greater.

“We are excited to add the F770 machine, with Stratasys’ known track record for durability and reliability, to our fleet of 3D printers,” said Mack Prototype President Greg Cebular. “The new machine will allow us to print large parts as a single piece without needing to bond parts together, with applications ranging from producing large prototypes to large master patterns used in cast urethane molding and low-volume, batch runs of parts of various sizes.”

In the last 18 months, Mack Prototype has bolstered its additive manufacturing capabilities with more than $875,000 in investments in equipment and infrastructure. In addition to the Stratasys, the Company’s fleet includes a smaller format FDM printer, along with Carbon CLIP Digital Light Synthesis (DLS), HP Multi Jet Fusion (MJF) and Formlabs Stereolithography (SLA) machines. Whether its prototyping or production parts, the breadth of Mack Proto’s 3D printing services allows customers to match production solutions with their cost, material and end use parameters, while speeding up the product development lifecycle.

“From just a few parts to as many as a few thousand, our team of engineers can help customers with their low-volume and bridge production requirements with flexible solutions designed to deliver high-quality parts while reducing time and cost,” Cebular added. “Even better, if those production needs change we are prepared to help customers meet volume demand with traditional tooling, rapidly scaling production here or at one of Mack’s larger manufacturing centers.”

New Talent

Mack Prototype has matched its capital equipment investments by bringing in new team members to support the Company’s growing customer base.

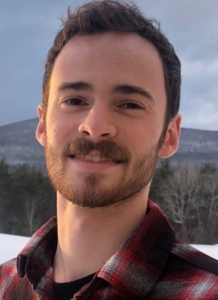

Eric Boyce has been appointed Purchasing & Compliance Manager, with responsibility for handling all vendor/supplier relations, as well as ISO, FDA and UL certifications, registrations, audits and other compliance matters. Boyce brings more than 15 years of custom manufacturing and ISO experience to the role. He most recently served as plant manager for Worthen Industries Nyclo Division in Clinton, Mass., where he was responsible for all building and personnel functions. Boyce also played a significant role in leading document creation and control activities, including production process controls and ISO documents, along with associated training activities.

Eric Boyce has been appointed Purchasing & Compliance Manager, with responsibility for handling all vendor/supplier relations, as well as ISO, FDA and UL certifications, registrations, audits and other compliance matters. Boyce brings more than 15 years of custom manufacturing and ISO experience to the role. He most recently served as plant manager for Worthen Industries Nyclo Division in Clinton, Mass., where he was responsible for all building and personnel functions. Boyce also played a significant role in leading document creation and control activities, including production process controls and ISO documents, along with associated training activities.

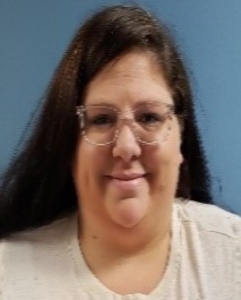

Rhonda Fox has joined the team as Office Manager, leading office and administrative duties, including accounting, accounts receivable, accounts payable and human resources. Fox brings more than 40 years of experience in manufacturing, including 10 years as an assistant plant manager. Prior to Mack Proto, she was office manager/assistant plant manager for Eustis Enterprises in Ashburnham, Mass., where she was responsible for bookkeeping, human resources, serving as a contact for vendors and general front-end office management. She also previously gained experienced as a payroll and human resources specialist with Resource Management, Inc., in Fitchburg, Mass.

Rhonda Fox has joined the team as Office Manager, leading office and administrative duties, including accounting, accounts receivable, accounts payable and human resources. Fox brings more than 40 years of experience in manufacturing, including 10 years as an assistant plant manager. Prior to Mack Proto, she was office manager/assistant plant manager for Eustis Enterprises in Ashburnham, Mass., where she was responsible for bookkeeping, human resources, serving as a contact for vendors and general front-end office management. She also previously gained experienced as a payroll and human resources specialist with Resource Management, Inc., in Fitchburg, Mass.

“Eric and Rhonda bring significant experience and energy to Mack Prototype,” Cebular said, “and they will be great assets to the team as we continue to deliver complex prototyping and low-volume production services to our customers.”

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 12 facilities throughout the world. Will Kendall is President and CEO. For more information, go to www.mack.com.

About Mack Prototype

Mack Prototype offers 75,000 square feet of manufacturing in an ISO 13485 certified environment for prototyping and low-volume production. With rapid manufacturing services, including 3D printing and additive manufacturing; cast urethane molding; plastic injection molding; CNC machining; and NPI Launch Lab, Mack Prototype can take products from prototype to production. For more information, visit www.mackprototype.com.

# # #