The Mack team headed to Design-2-Part (D2P) New England Oct. 15-16, 2025, at the Royal Plaza Trade Center in Marlborough, Mass. Be sure to visit us [...]

Exploring the Right 3D Printing Process for Your Project at Mack Prototype At Mack Prototype, we know that not all 3D printers—or printed parts—are created [...]

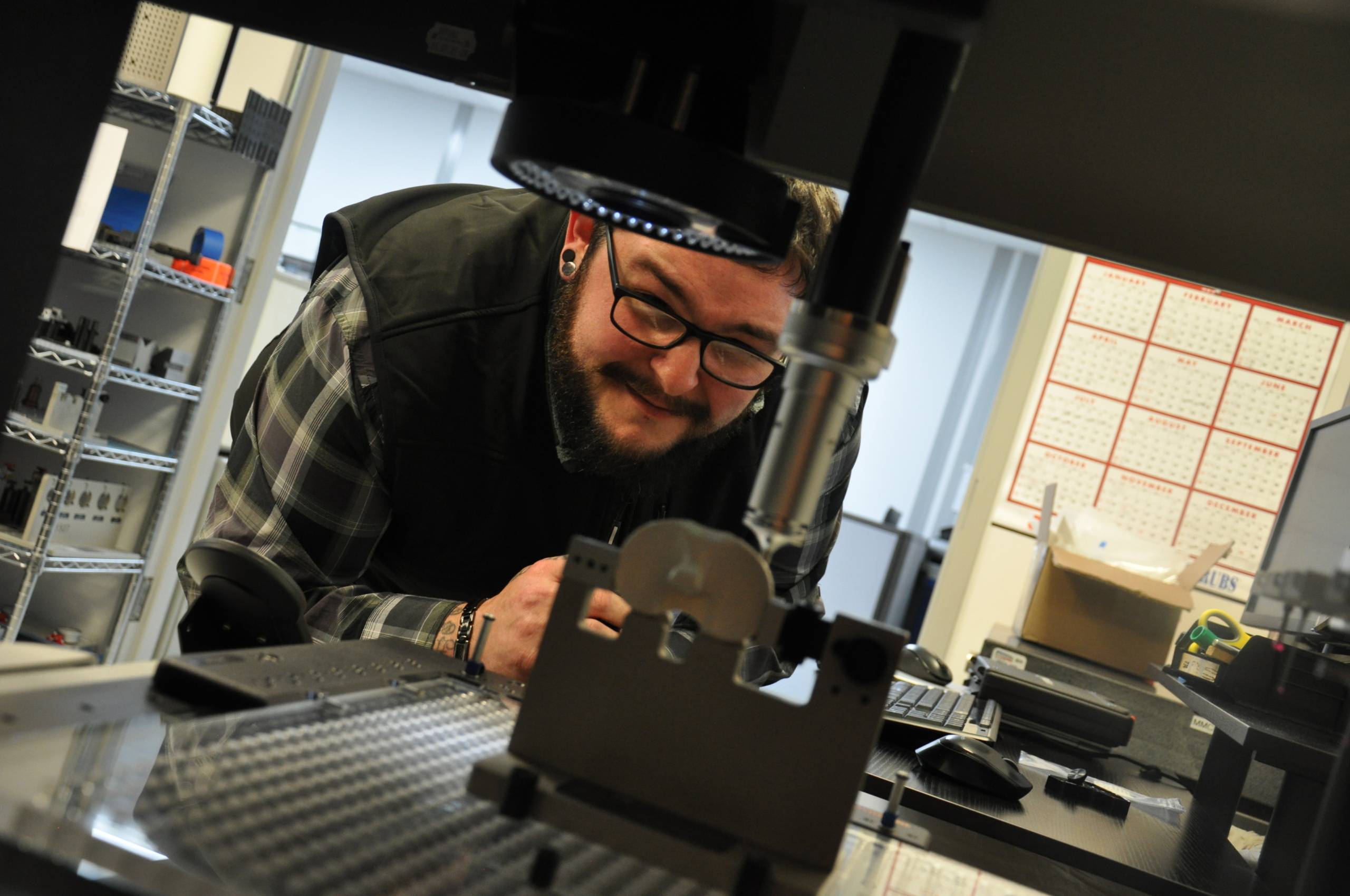

At Mack Molding, quality and precision are at the core of what we do—and that starts with metrology. With state-of-the-art equipment, expanded capabilities, and a [...]

Hope Kavulich, Product Realization Engineer at Synectic Product Development, a wholly-owned subsidiary of Mack Group, recently sat down with The Manufacturing Shake-Up podcast to share [...]

Mack Molding’s Sheet Metal Fabrication Department has taken a major step forward in precision finishing with the addition of a new VibeTech Deburring Machine at [...]

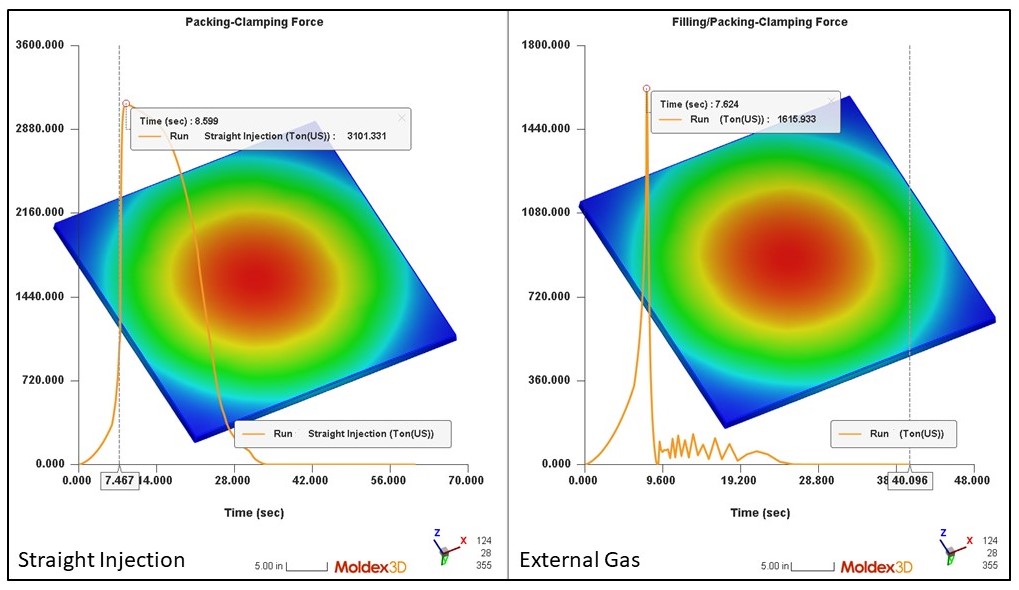

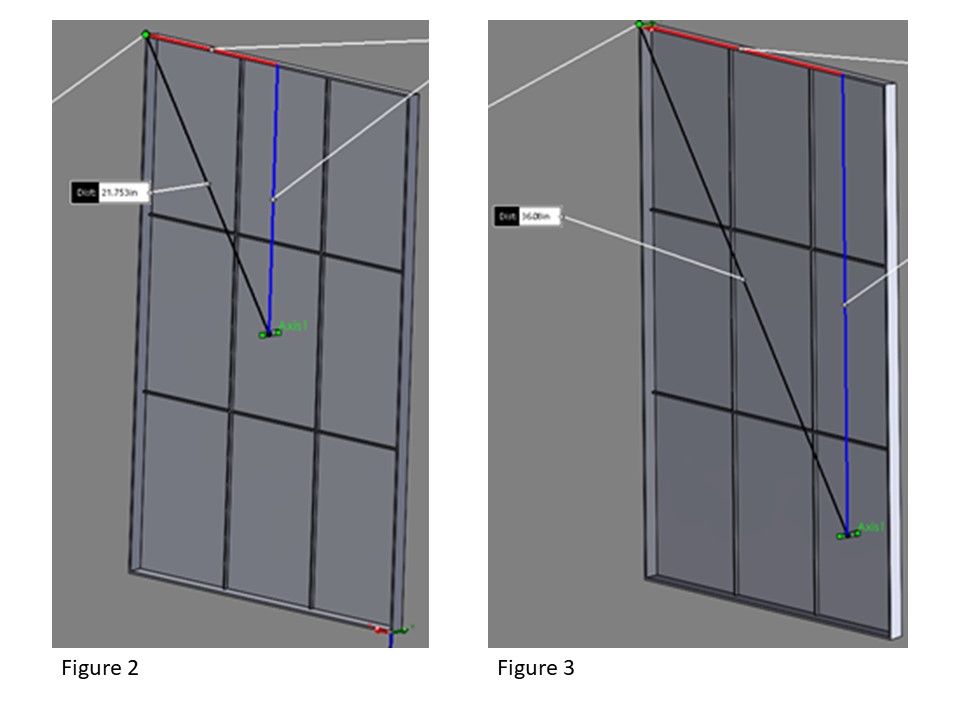

Gas-assist molding, which utilizes nitrogen gas pressure to form a part fully, offers significant cost-saving advantages while expanding design and manufacturing options for injection-molded components. [...]

What is Cast Urethane? Cast urethane is the process of pouring liquid polyurethane resin into a rubber mold to create a part. It is a [...]

For Lucas Osorio, Mack Molding has been more than just a place to work – it’s been a foundation for personal and professional growth through [...]

Mack Molding’s plastic injection molding and contract manufacturing experts are counting down the days until MD&M West 2025, taking place Feb. 4-6, 2025, at the Anaheim Convention Center. The team [...]

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our Privacy Policy.I Accept Mack Prototype turned 25 this year [...]

In the world of injection molding, optimizing the quality of molded parts is paramount. Two critical factors that play a significant role in this optimization [...]

Mack Molding has long been recognized for its contributions to the plastics industry, and this year, the spotlight shines brightly on three remarkable women who [...]

The Mack team headed to Design-2-Part (D2P) New England Oct. 16-17, 2024, at the Royal Plaza Trade Center in Marlborough, Mass. Be sure to visit [...]

Use promo code SPECIAL24 for a free expo pass and 20% off a 2-day conference pass The Mack Molding team is in Charlotte, N.C., for MD&M [...]

Mack Molding is hitting the road once again, and this time the team is heading to Atlanta for Design-2-Part Southeast – affectionately known as D2P [...]

Essentially every resin processed at Mack is a compound made up of multiple components. This can include UV stabilizers or flame inhibitors, but the most [...]