In the world of injection molding, optimizing the quality of molded parts is paramount. Two critical factors that play a significant role in this optimization process are gate location and flow ratio. Properly understanding and managing these elements can make the difference between a successful, high-quality part and having an incomplete part that can’t be filled. Let’s delve into how gate location and flow ratio interact, and why careful consideration of these factors is essential.

The Importance of Gating in Injection Molding

Injection molding commonly utilizes six types of gates, each with its unique application:

- Direct Sprue

- Edge-/Tab-gate

- Fan-gate

- Sub-/Cashew-/Banana-gate

- Diaphragm

- Pinpoint (for hot drops)

The location of these gates can significantly impact the quality of the final product. For example, improper gate placement might cause early freeze-off, leading to short-shots or improper filling due to inadequate machine pressure. To mitigate these issues, it’s crucial to follow specific guidelines when determining gate placement:

- Place the gate at the part’s largest wall thickness.

- Ensure the gate is positioned to minimize the flow length.

- Consider the cosmetic implications of gate placement.

By adhering to these guidelines, the risk of defects is minimized, resulting in a higher-quality product.

Understanding Flow Ratio and Its Implications

Flow ratio, defined as the distance between the gate and the farthest point of the part in relation to wall thickness, is a key metric in ensuring proper part filling (Equation 1). Choosing the best gate type, location and quantity minimizes the flow length and optimizes the flow ratio. The industry standard, as provided by RJG, suggests that the flow ratio should be kept under 150. At Mack, however, a stricter standard of 100 is applied to provide an increased factor of safety.

Equation 1: Flow Ratio = Flow Length / Wall Thickness

A poor flow ratio can lead to several issues, including:

- Longer fill times

- Pressure spikes

- Compromised part strength

- Formation of knit lines or seams, creating weak points

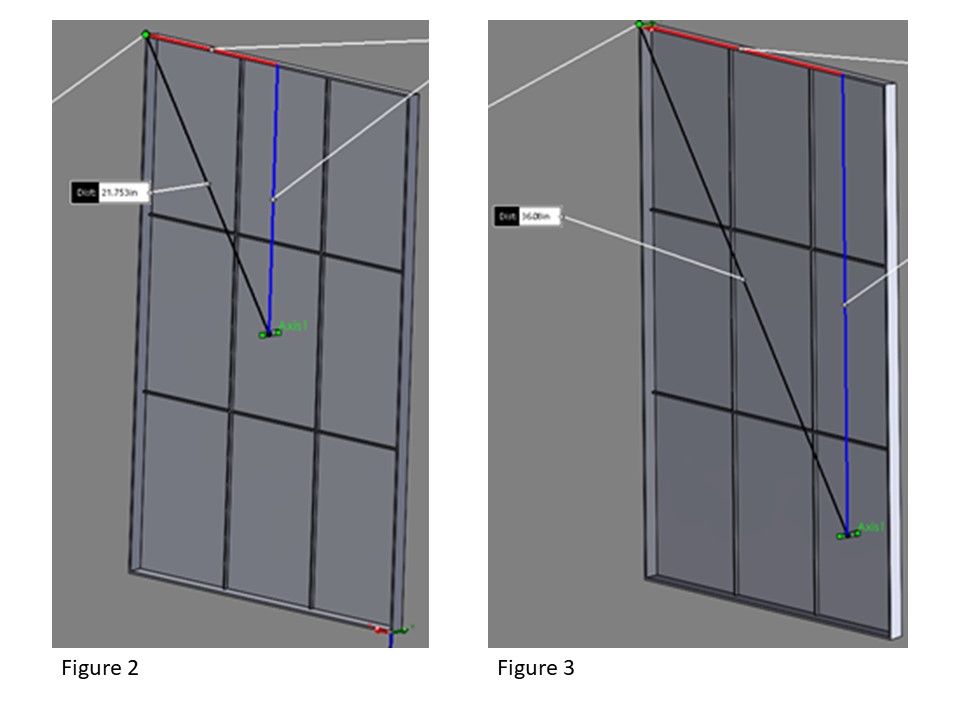

For instance, consider Figure 2, a part with a flow length of 21.753 inches and a wall thickness of 0.16 inches, resulting in a flow ratio of 135.97 . This falls within the industry standard, but to meet Mack’s more stringent requirement, a second gate might be added to lower the ratio below 100. In contrast, Figure 3 is a part with a 36.08-inch flow length would result in a flow ratio of 225, which is well outside acceptable standards and would require significant adjustments.

Balancing Gate Location and Flow Ratio

In some cases, sub-optimal gating methods or locations are necessary to preserve the cosmetic quality of the part or accommodate complex geometries. However, these compromises often lead to increased flow ratios. So, how can this challenge be addressed?

One solution is the use of flow leaders. These are raised paths—typically 1 inch wide and 1 millimeter (0.0394 inches) high with heavy drafting—that help manage the flow of material through the mold. Flow leaders reduce unwanted shear and air pockets, eliminate the need for multiple gates, and increase wall thickness, thereby lowering the flow ratio and reducing pressure spikes.

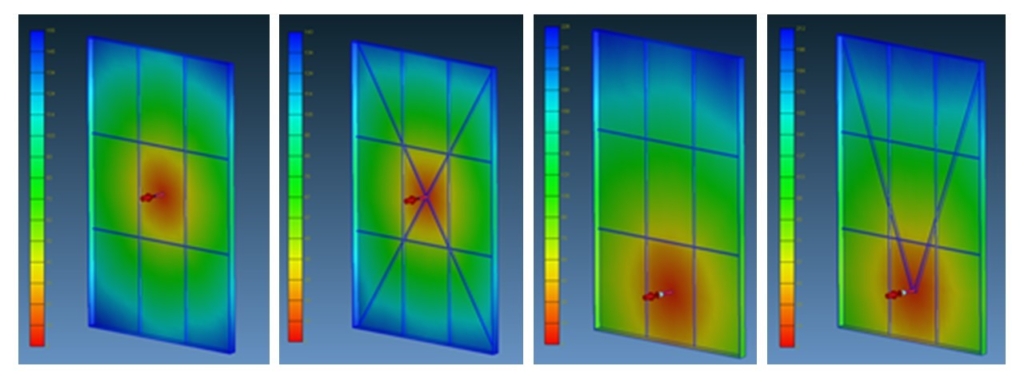

Improper gate placement, on the other hand, can cause several issues, including fill imbalance, air pockets, uneven cooling, shrinking, warping, and short-shots. The use of Moldex simulations can provide valuable insights into how different gate placements and flow leaders impact the filling process, helping engineers make informed decisions.

Figure 4: A gradient showing the flow length/wall thickness for each scenario: good sprue placement, good sprue placement with flow leaders, bad sprue placement, and bad sprue placement with flow leaders, respectively.

Conclusion

Understanding the relationship between gate location and flow ratio is critical in injection molding. By carefully considering gate placement, flow ratio, and the use of flow leaders, engineers can significantly improve the quality of molded parts. At Mack, we prioritize these factors to ensure that our products not only meet industry standards but exceed them, delivering high-quality, defect-free parts to our customers.

For more information on this topic, or any of your plastic injection molding needs, please feel free to reach out to us!

Dwalin DeBoer’s journey into the plastics industry began with a love for chemistry in high school, which led her to pursue a degree in chemical engineering at Worcester Polytechnic Institute. Her early hands-on experience at Monsanto Plastics solidified her passion for polymers, setting the stage for a successful career. Today, DeBoer leads a 13-person business unit at Mack Molding, overseeing account management, program management, and customer service for 51 clients.

Dwalin DeBoer’s journey into the plastics industry began with a love for chemistry in high school, which led her to pursue a degree in chemical engineering at Worcester Polytechnic Institute. Her early hands-on experience at Monsanto Plastics solidified her passion for polymers, setting the stage for a successful career. Today, DeBoer leads a 13-person business unit at Mack Molding, overseeing account management, program management, and customer service for 51 clients. Casey Tsougranis, the Director of Business Development at Mack Prototype Inc., exemplifies the blend of technical expertise and business acumen required to succeed in the plastics industry. After earning her degree in management engineering with a concentration in chemistry, Tsougranis joined Mack Molding as a business development manager. Her internship in program management provided her with invaluable exposure to the validation processes of the orthopedic industry, which fueled her interest in molding processes.

Casey Tsougranis, the Director of Business Development at Mack Prototype Inc., exemplifies the blend of technical expertise and business acumen required to succeed in the plastics industry. After earning her degree in management engineering with a concentration in chemistry, Tsougranis joined Mack Molding as a business development manager. Her internship in program management provided her with invaluable exposure to the validation processes of the orthopedic industry, which fueled her interest in molding processes. As the Materials Manager at Mack Molding, Ann Wedell plays a crucial role in ensuring the smooth flow of materials and the timely delivery of products. Wedell’s career began in the pulp and paper industry, where she honed her skills as a process engineer before transitioning to the plastics industry. At Mack Molding, she has held various roles, including quality engineer and manufacturing engineer, before stepping into her current position.

As the Materials Manager at Mack Molding, Ann Wedell plays a crucial role in ensuring the smooth flow of materials and the timely delivery of products. Wedell’s career began in the pulp and paper industry, where she honed her skills as a process engineer before transitioning to the plastics industry. At Mack Molding, she has held various roles, including quality engineer and manufacturing engineer, before stepping into her current position.