INDUSTRIAL

Mack Molding

Industrial Market Solutions

Mack Molding is a trusted industrial equipment contract manufacturing partner for industrial OEMs, offering a comprehensive suite of services designed to streamline production, enhance product performance, and accelerate time to market. Our expertise in large-part molding, precision machining, sheet metal fabrication, high-speed painting, value-added assembly, painting and finishing, and warehousing and distribution ensures we can meet the most demanding manufacturing challenges.

Mack Molding is a trusted industrial equipment contract manufacturing partner for industrial OEMs, offering a comprehensive suite of services designed to streamline production, enhance product performance, and accelerate time to market. Our expertise in large-part molding, precision machining, sheet metal fabrication, high-speed painting, value-added assembly, painting and finishing, and warehousing and distribution ensures we can meet the most demanding manufacturing challenges.

Industrial Markets We Serve

Mack Molding partners with OEMs across a wide range of industries, providing tailored industrial equipment contract manufacturing solutions for:

- Office & mailing systems

- Lawn & garden

- Material Handling & Power Equipment

- HVAC & Water Management Systems

Food Service Equipment

Food Service Equipment- Structural & Industrial Components

- Furniture & Flooring

- Consumer & Commercial Electronics

- Server & mass storage

- Clean air systems and environmental filters

Whether you need high-performance industrial components, complex electro-mechanical assemblies, or large-scale molded parts, Mack Molding has the expertise and capacity to deliver.

End-to-End Industrial Equipment Contract Manufacturing Capabilities

As an extension of your manufacturing arm, Mack Molding provides an integrated approach to enclosure and product manufacturing, starting from product design and development through to final assembly and distribution. Our vertical integration simplifies the supply chain and allows us to take your product from concept to completion, including:

- Custom injection molding – Expertise in a wide range of materials, including advanced composites and proprietary blends.

- Sheet metal fabrication – Precision cutting, forming, and finishing for high-strength enclosures and components.

Full-service machining – CNC machining, tool-making, and secondary finishing.

Full-service machining – CNC machining, tool-making, and secondary finishing.- Automated high-speed painting – Class A and functional coatings for enhanced durability and aesthetics.

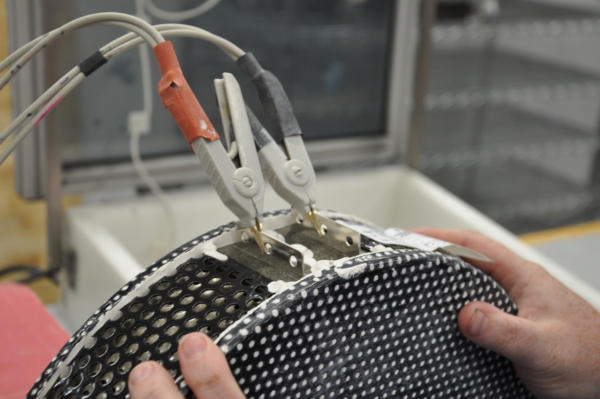

- Electro-mechanical assembly – From simple sub-assemblies to fully integrated products.

- Warehousing & distribution solutions – Flexible inventory models to support just-in-time manufacturing.

Driving Innovation in Industrial Applications

With more than 100 years of manufacturing expertise, Mack Molding partners with leading companies in power equipment, material handling, HVAC, water management, and commercial products. Whether it’s designing for manufacturability, optimizing costs, or ensuring product quality, we provide solutions that help OEMs succeed in a competitive marketplace.

Proven Success Stories

Proven Success Stories

- Advanced Pumping System – Mack Molding provides insert molding, overmolding with a proprietary TPE blend, and gas-assist molding to create a functional channel that enhances pump performance in rugged applications.

- Next-Generation Automated Blender – Mack Molding’s vertically integrated approach enabled the rapid development of a complex electro-mechanical device featuring over 400 unique components. Services included rapid prototyping, external gas-assist molding, sheet metal fabrication, and full product assembly.

- Innovative Flooring Solution – We engineered an interlocking, moisture-resistant flooring system made from recycled materials, ensuring both sustainability and easy installation without the need for adhesives.

Case Studies

Read about Mack Molding’s Industrial Case Studies.

Read about Mack Molding’s Industrial Computer Business Case Studies.

Read about Mack Molding’s Industrial Consumer Case Studies.

Ready to Get Started?

Contact us today to discuss how we can bring your industrial products to life with precision manufacturing, supply chain optimization, and innovative engineering solutions.