ARLINGTON, Vt. (Feb. 7, 2017) – Mack Molding, a leading custom plastics molder and supplier of contract manufacturing services, utilizes several tools, including workforce cultivation, prudent fiscal planning and vertically-integrated services, to position itself for future success. Today the Company announces the addition of a core competency program to its toolbox, ensuring employees are prepared to meet customers’ increasingly sophisticated needs.

Mack’s first graduates from the Company’s core competency training program, dubbed Mack U: Jim Cook, Tyler Willette, Lucas Cross, Nelson Nieves, Amanda Adams, Sarah Warren and John Morin.

Dubbed Mack U, the program recently graduated its first seven students from the initial curriculum, Electro-Mechanical Operator I. In all, the graduates completed 14 courses and 21 hours of classroom time and hands-on training. To receive certification, successful trainees must demonstrate their proficiency through tests, on which they must score a 90 or better.

“We believe employees are the Company’s most valuable assets,” said Headquarters Plant Manager Rich Hornby. “We developed Mack U because our work is getting more complex, making the quality of our output more important than ever. We carefully looked at what we are doing and where we are going, and this program gives our team the tools needed to meet the demands of our customers, as well as a pathway for advancement.”

According to Hornby, the initial program was foundational, helping to improve safety awareness and explain the reasoning behind Mack systems. They tapped into the talents of 12 veteran Mack employees who channeled their expertise to become subject experts and develop courses on topics like customer communication, electrostatic discharge and wiring assemblies.

While there are seven employees in the first graduating class, a significant number continue working toward certification. Moving forward, the trainees will take on Electro-Mechanical Operator Levels II and III in which they will be introduced to advanced topics such as drawing and wire schematics, pneumatic connections and plumbing, soldering and the integration of firmware, software and hardware. Additionally, Mack will be rolling out a molding program.

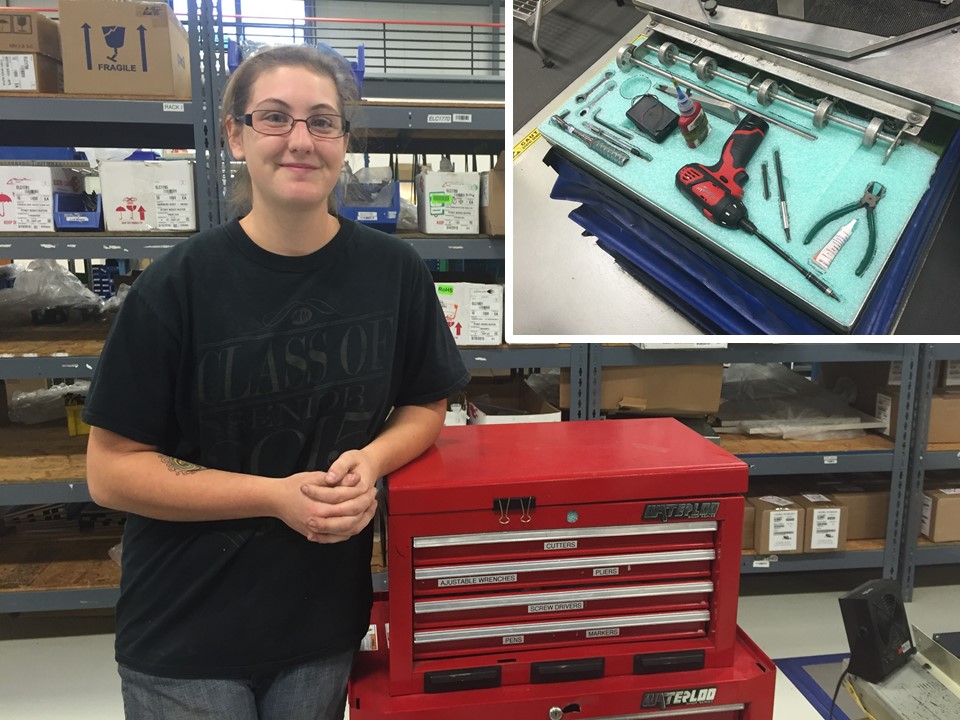

Mack Finishing Operator Sarah Warren has used what she learned in the 5S class both at work and in her personal life.

If an improved customer experience and being better prepared to deal with marketplace changes was not enough, the trainees also are benefitting personally. Finishing Operator Sarah Warren used what she learned in the 5S class to alter the way she sets up her tool box, taking her organization skills to the next level.

“It’s made everything easier to find, and I am working more efficiently,” Sarah said. “This is my first job, so this is totally new to me. I am even using what I learned at home, just yesterday I was talking to my dad about the state of his toolbox!”

Since taking the classes, Sarah’s classmates have used their newly gained knowledge to make recommendations on calibration and raise important questions about materials, enhancing their value to Mack and its customers.

“As a ninety-six year old company we have a lot of knowledge and an intimate relationship with manufacturing, but organizing like this is truly a first for us,” Hornby said. “By establishing foundational skills, and then building on them, we are creating a team that will be unsurpassed in skill and quality of work – ensuring Mack continues to serve as the manufacturing arm for current, and new, customers, well into our next century as an organization.”

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

# # #

Contact: Larry Hovish

(802) 375-0772

larry.hovish@mack.com

Well done team one.

To Rich, Nancy and the subject matter experts: great job keeping this moving and receiving these results. A benefit for everyone: people, Mack and customers.