SERVICES WE PROVIDE

Mack Molding – Contract Manufacturing & Injection Molding Services

From design to delivery, integrated services built for complex manufacturing needs

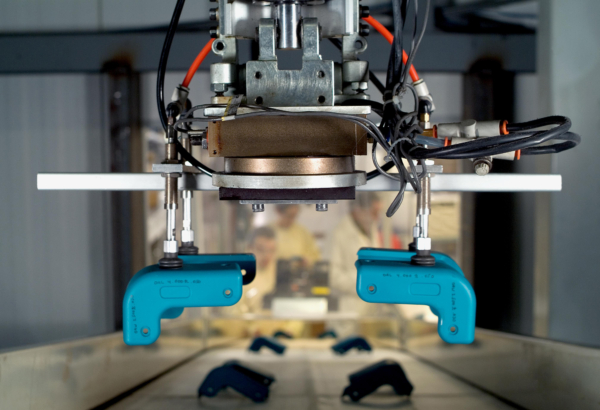

Mack Molding is a vertically integrated contract manufacturer supporting world-class companies in the medical, industrial, transportation, robotics, and energy & utilities markets.

With deep capabilities in injection molding, design & development, sheet metal fabrication, machining, prototyping, and turnkey assembly, we help customers bring complex products to market—faster, smarter, and more cost-effectively.

From Concept to Completion

We can engage at any stage of your product lifecycle—from early design and prototyping to full-scale production and fulfillment. With three facilities dedicated to product development and tooling, we provide a seamless transition from concept to production, reducing risk, accelerating timelines, and maintaining tight control over cost and quality.

Our Core Capabilities

Design & Development – Integrated engineering support, DFM analysis, and advanced CAD/CAE tools to streamline product development and accelerate time-to-market.

Design & Development – Integrated engineering support, DFM analysis, and advanced CAD/CAE tools to streamline product development and accelerate time-to-market.- Prototyping – Rapid prototyping, soft tooling, and 3D printing services to support design validation, functional testing, and early-stage iterations.

- Plastic Injection Molding – 120+ presses from 28 to 4,000 tons, offering capabilities in large-part, gas-assist, structural foam, and two-shot molding—supported by in-house tooling and scientific molding expertise.

- Machining & Sheet Metal Fabrication – Precision components fabricated in-house through CNC machining, laser cutting, bending, welding, and finishing—from prototype to production volumes.

- Painting, Finishing & Secondary Operations – Class A painting, pad printing, ultrasonic welding, heat staking, and other value-added processes that enhance product appearance, durability, and functionality.

- Assembly & Contract Manufacturing – Turnkey system-level assembly of mechanical, electronic, and electromechanical products—including Class III PMA medical devices—with capabilities in testing, integration, packaging, and fulfillment.

- Global Supply Chain Management & Fulfillment – End-to-end sourcing, procurement, inventory management, and logistics solutions that support product launches and customer-owned inventory programs.

One Partner. Total Responsibility.

With five U.S. facilities and over a century of experience, Mack Molding delivers a tightly integrated approach that eliminates the friction of multiple vendors. Our ability to launch both plastic and metal components from a single location offers major advantages in cost, time-to-market, and quality—particularly for customers needing close coordination between materials and disciplines.

We support everything from early-stage prototypes to build-to-order system assembly, backed by robust internal systems for supply chain management, test development, data tracking, and inventory control.

Strategic Locations to Serve our Customers

Mack Molding provides custom plastic injection molding and contract manufacturing services through a vertically integrated network of facilities in the Northeast and Southeast U.S. From our New England operations in Vermont, serving nearby states such as Massachusetts, New Hampshire, Connecticut, New York, and Pennsylvania, to our presence in North Carolina and South Carolina, with easy access to Georgia, Tennessee, Virginia, Florida, and Alabama, we combine regional accessibility with world-class manufacturing expertise. Our footprint across the Northeast and the Carolinas allows us to deliver precision molding, large-part production, and complete assemblies where our customers need them most. With advanced technology, engineering support, and strict quality systems, Mack ensures complex products are launched efficiently and built to the highest standards.

Let’s Bring Your Product to Life

Whether you’re developing a next-gen surgical device, scaling industrial equipment, or launching a robotics platform—Mack Molding is ready to help you make it real.

Contact us to learn more about how we can support your next program.