PLASTIC INJECTION MOLDING

Mack Molding

Plastic Injection Molding Precision, Efficiency & Scalability

Plastic Injection Molding Precision, Efficiency & Scalability

Plastic injection molding is a versatile, cost-effective solution for producing parts across industries, including medical, industrial, transportation, robotic, and energy and utility applications. This process offers high precision, repeatability, and efficiency, making it ideal for everything from commodity components to complex, tight-tolerance parts.

The Plastic Injection Molding Process

Injection molding follows a consistent, scalable process:

- Tooling: A custom mold tool is fabricated with a cavity that shapes the final part.

- Molding: Thermoplastic resin is melted and injected into the mold under high pressure.

- Cooling & Ejection: The part cools, solidifies, and is ejected for finishing or assembly.

With fast cycle times and minimal secondary processing, injection molding is one of the most cost-effective production methods at scale.

Why Mack?

Why Mack?

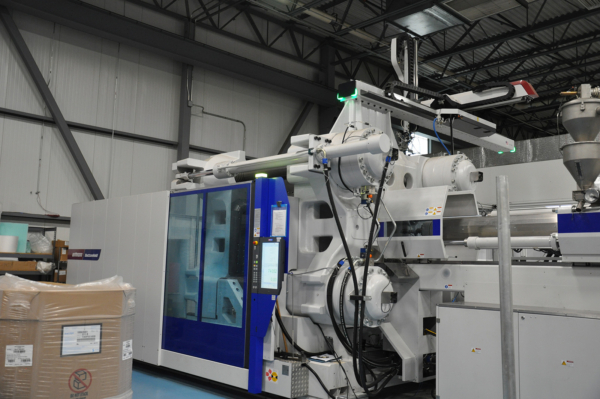

Mack Molding brings over 100 years of expertise in custom plastic molding. Our capabilities include:

- 120+ injection molding machines (28 to 4000 tons, 0.6 to 800 oz shot sizes)

- Diverse materials expertise from commodity plastics to high-performance resins

- Design for Manufacturability (DFM), Assembly (DFA), and Testing (DFT) support

- Global supply chain management to ensure efficiency and reliability

Specialized Plastic Injection Molding Capabilities

We employ advanced molding techniques tailored to enhance strength, reduce weight, and accommodate complex geometries. Our expertise includes working with high-performance materials such as composites, Polyetherimide (PEI) branded as Ultem™, and Polyetheretherketone (PEEK). By integrating these materials with specialized molding processes, we deliver components that meet stringent performance criteria across various industries.

- Structural Foam Molding – Ideal for large, rigid parts like robotic frames.

- External Gas Assist – Lowers press tonnages, reduces stress/distortion, enables thicker sections.

- Internal Gas Assist – Molds extremely thick sections with high aesthetic quality.

- Overmolding & Insert Molding – Molds multiple materials together for enhanced function and aesthetics.

Comprehensive Secondary Processes & Finishing Solutions

Comprehensive Secondary Processes & Finishing Solutions

Mack Molding offers more than just injection molding—we provide end-to-end manufacturing solutions tailored to your needs. Whether you require a full manufacturing partnership or select secondary operations, our modular approach ensures a streamlined, cost-effective process designed around your requirements.

Precision Assembly & Finishing

Beyond molding, Mack provides mechanical and electronic assembly alongside extensive secondary operations, including:

-

- Decorating & Branding – Heat sealing, pad printing, hot stamping

- Advanced Finishing – Class A, soft-touch, and metallic coatings

- High-Volume Painting – Robotic painting, EMI/RFI shielding, custom masking

Power of Automation

Power of Automation

Our investment in robotic painting, precision masking, and automated material handling optimizes:

- Quality & Consistency – Minimizing defects, ensuring repeatability

- Cost Efficiency – Lowering labor costs and material waste

- Scalability – Expanding capacity for growing demand

The Mack Advantage: A One-Stop Solution

Few molders combine world-class injection molding, high-end finishing, and automation under one roof. Mack Molding does—delivering efficiency, quality, and cost savings at every stage of production.

Plastic Injection Molding: From Concept to Production

As one of North America’s top 10 non-automotive custom molders, Mack supports customers from prototyping to full-scale production. Our five U.S. facilities in Vermont, North Carolina and South Carolina provide world-class molding solutions to global markets.

Ready to optimize your plastic injection molding project? Contact us today!