In honor of Manufacturing Day, Mack is taking a moment to reflect on tomorrow’s manufacturers, engineers and leaders by looking back at the Company’s 2017 internship program. Join us for an inside look at how students are making a difference at Mack and launching careers.

Mack Announces Additions to Team

Growing Molder & Contract Manufacturer Recruiting at a Steady Pace

ARLINGTON, Vt. (June 13, 2017) – Spring has sprung in the Green Mountains of Southern Vermont, bringing with it hues of the state’s namesake and a new crop of employees to Mack Molding’s headquarters ready to deliver on the Company’s mission of total customer satisfaction.

The addition of new talent coincides with investments in capital equipment, bolstering a period of growth that promises to position Mack to ensure the Company, and its customers’, success well into the future. The Company’s newest recruits include five former interns who have chosen to officially begin their careers with Mack. The internship program is the keystone of the Company’s workforce development efforts, and a testament to its success as 11 students have now returned to the Company full time in the last two years.

“Welcoming interns back to us full-time after the commencement season is starting to become a tradition,” said Mack Molding President Jeff Somple. “It is a rewarding and valuable experience as they bring a unique combination of fresh insights and familiarity with our organization. While we often focus on the success of Mack’s mobilization of the industry’s next generation, it is important to note we are filling positions at all levels of experience and across the organization. The business has seen four consecutive years of excellent growth, and recruiting high-quality, skilled professionals and engineers is key to maintaining that momentum. It is an exciting time here, and with dozens of positions being filled from the shop floor to engineering to the front office, the time is right start your career with Mack.”

Former intern Tracy Weinstein is no stranger to the Mack, bringing a deep familiarity with the Company and its processes to her new position as a manufacturing engineer. Tracy earned a bachelor of science degree in biomedical engineering from the Rensselaer Polytechnic Institute (RPI) in Troy, N.Y., with minors in general psychology and marketing. The manufacturing experience and medical product insight she garnered during her tenure as an intern, coupled with the knowledge she gained as a student at RPI, will serve her well in this new position.

Former intern Tracy Weinstein is no stranger to the Mack, bringing a deep familiarity with the Company and its processes to her new position as a manufacturing engineer. Tracy earned a bachelor of science degree in biomedical engineering from the Rensselaer Polytechnic Institute (RPI) in Troy, N.Y., with minors in general psychology and marketing. The manufacturing experience and medical product insight she garnered during her tenure as an intern, coupled with the knowledge she gained as a student at RPI, will serve her well in this new position.

Mack has welcomed Casey Magrath as a business development manager. A recent graduate of the Worcester Polytechnic Institute (WPI), Casey has a bachelor of science degree in management engineering with a concentration in chemistry. She is currently working on her master of science degree in management at WPI. Prior to joining the Company full time, she was a Mack intern, developing valuable product development and validation experience while working with orthopedic customers. Casey also developed her sales and relationship development skills as an athenahealth intern in Watertown, Mass.

Mack has welcomed Casey Magrath as a business development manager. A recent graduate of the Worcester Polytechnic Institute (WPI), Casey has a bachelor of science degree in management engineering with a concentration in chemistry. She is currently working on her master of science degree in management at WPI. Prior to joining the Company full time, she was a Mack intern, developing valuable product development and validation experience while working with orthopedic customers. Casey also developed her sales and relationship development skills as an athenahealth intern in Watertown, Mass.

Trevor Pollock joined Mack as a supplier quality technician in March 2017 and was recently promoted to supplier engineer, ensuring Mack suppliers meet customers’ quality expectations. Prior to Mack, Trevor designed an energy system for a landfill gas power plant and assembled a grant proposal for research on the effect of a gene on bone loss during space flight at the University of Colorado Boulder, where he received his master of science in mechanical engineering. Trevor also has a bachelor of arts in mathematics with minors in physics and economics from Vermont’s Middlebury College.

Trevor Pollock joined Mack as a supplier quality technician in March 2017 and was recently promoted to supplier engineer, ensuring Mack suppliers meet customers’ quality expectations. Prior to Mack, Trevor designed an energy system for a landfill gas power plant and assembled a grant proposal for research on the effect of a gene on bone loss during space flight at the University of Colorado Boulder, where he received his master of science in mechanical engineering. Trevor also has a bachelor of arts in mathematics with minors in physics and economics from Vermont’s Middlebury College.

Kyle Pilote has been appointed as a supplier engineer within the purchasing organization. Prior to Mack, Kyle served as maintenance and facilities manager at NSK in Bennington, Vt., where he was previously a manufacturing engineer. He also was a manufacturing engineer for Allred Associates and Val-Tech Holdings. Kyle has a bachelor of science degree in mechanical engineering from the Rochester Institute of Technology. As a supplier engineer, he will ensure Mack customers receive the highest quality parts.

Kyle Pilote has been appointed as a supplier engineer within the purchasing organization. Prior to Mack, Kyle served as maintenance and facilities manager at NSK in Bennington, Vt., where he was previously a manufacturing engineer. He also was a manufacturing engineer for Allred Associates and Val-Tech Holdings. Kyle has a bachelor of science degree in mechanical engineering from the Rochester Institute of Technology. As a supplier engineer, he will ensure Mack customers receive the highest quality parts.

Colin Derby, who spent two years in Mack’s internship program, has joined the Company full-time as an associate manufacturing engineer. A graduate of Randolph-based Vermont Technical College, he earned his associate’s degree in mechanical engineering technology and bachelor’s degree in manufacturing engineering technology. In addition to his Mack internship, Colin gained manufacturing and machining experience during internships at Plasan Carbon Composites, Kaman Aero Space and Abacus Automation.

Colin Derby, who spent two years in Mack’s internship program, has joined the Company full-time as an associate manufacturing engineer. A graduate of Randolph-based Vermont Technical College, he earned his associate’s degree in mechanical engineering technology and bachelor’s degree in manufacturing engineering technology. In addition to his Mack internship, Colin gained manufacturing and machining experience during internships at Plasan Carbon Composites, Kaman Aero Space and Abacus Automation.

Cody LaFlamme has joined Mack’s purchasing team as a cost estimator; however, he first entered the doors as an intern in 2014. During his tenure as an intern, Cody became familiar with Mack’s supplier base while gaining experience in ERP navigation, as well as quality and risk assessments. A graduate of the State University of New York at Oswego, he has a bachelor’s degree in technology management with minors in business administration and athletic coaching.

Cody LaFlamme has joined Mack’s purchasing team as a cost estimator; however, he first entered the doors as an intern in 2014. During his tenure as an intern, Cody became familiar with Mack’s supplier base while gaining experience in ERP navigation, as well as quality and risk assessments. A graduate of the State University of New York at Oswego, he has a bachelor’s degree in technology management with minors in business administration and athletic coaching.

Castleton University graduate Alex Hawley has accepted a position as a manufacturing clerk. Alex, who received a bachelor of business administration with a dual concentration in marketing and management, is already a familiar face around the office having spent four summers interning for Mack. As an intern, he worked on bills of materials, inventoried products and assisted the metal fabrication team while building keen insights into Mack’s operations.

Castleton University graduate Alex Hawley has accepted a position as a manufacturing clerk. Alex, who received a bachelor of business administration with a dual concentration in marketing and management, is already a familiar face around the office having spent four summers interning for Mack. As an intern, he worked on bills of materials, inventoried products and assisted the metal fabrication team while building keen insights into Mack’s operations.

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

###

Mack Training Program Builds Skills Needed for Future Growth

ARLINGTON, Vt. (Feb. 7, 2017) – Mack Molding, a leading custom plastics molder and supplier of contract manufacturing services, utilizes several tools, including workforce cultivation, prudent fiscal planning and vertically-integrated services, to position itself for future success. Today the Company announces the addition of a core competency program to its toolbox, ensuring employees are prepared to meet customers’ increasingly sophisticated needs.

Mack’s first graduates from the Company’s core competency training program, dubbed Mack U: Jim Cook, Tyler Willette, Lucas Cross, Nelson Nieves, Amanda Adams, Sarah Warren and John Morin.

Dubbed Mack U, the program recently graduated its first seven students from the initial curriculum, Electro-Mechanical Operator I. In all, the graduates completed 14 courses and 21 hours of classroom time and hands-on training. To receive certification, successful trainees must demonstrate their proficiency through tests, on which they must score a 90 or better.

“We believe employees are the Company’s most valuable assets,” said Headquarters Plant Manager Rich Hornby. “We developed Mack U because our work is getting more complex, making the quality of our output more important than ever. We carefully looked at what we are doing and where we are going, and this program gives our team the tools needed to meet the demands of our customers, as well as a pathway for advancement.”

According to Hornby, the initial program was foundational, helping to improve safety awareness and explain the reasoning behind Mack systems. They tapped into the talents of 12 veteran Mack employees who channeled their expertise to become subject experts and develop courses on topics like customer communication, electrostatic discharge and wiring assemblies.

While there are seven employees in the first graduating class, a significant number continue working toward certification. Moving forward, the trainees will take on Electro-Mechanical Operator Levels II and III in which they will be introduced to advanced topics such as drawing and wire schematics, pneumatic connections and plumbing, soldering and the integration of firmware, software and hardware. Additionally, Mack will be rolling out a molding program.

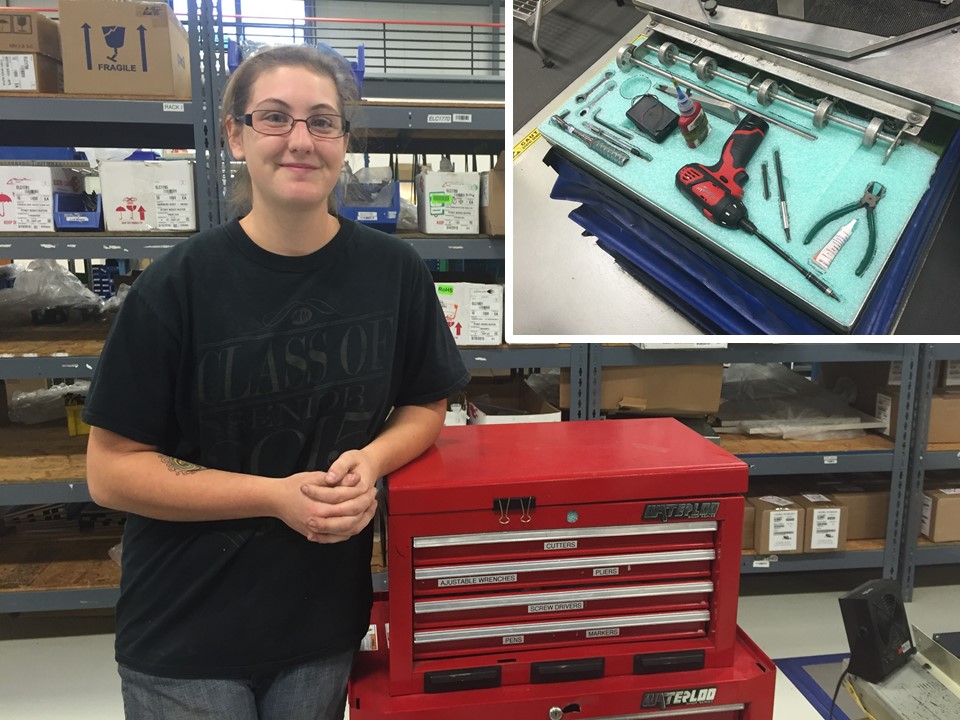

Mack Finishing Operator Sarah Warren has used what she learned in the 5S class both at work and in her personal life.

If an improved customer experience and being better prepared to deal with marketplace changes was not enough, the trainees also are benefitting personally. Finishing Operator Sarah Warren used what she learned in the 5S class to alter the way she sets up her tool box, taking her organization skills to the next level.

“It’s made everything easier to find, and I am working more efficiently,” Sarah said. “This is my first job, so this is totally new to me. I am even using what I learned at home, just yesterday I was talking to my dad about the state of his toolbox!”

Since taking the classes, Sarah’s classmates have used their newly gained knowledge to make recommendations on calibration and raise important questions about materials, enhancing their value to Mack and its customers.

“As a ninety-six year old company we have a lot of knowledge and an intimate relationship with manufacturing, but organizing like this is truly a first for us,” Hornby said. “By establishing foundational skills, and then building on them, we are creating a team that will be unsurpassed in skill and quality of work – ensuring Mack continues to serve as the manufacturing arm for current, and new, customers, well into our next century as an organization.”

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

# # #

Contact: Larry Hovish

(802) 375-0772

larry.hovish@mack.com

Mack Molding Offers Local Students an Inside Look at Operations

Made in Vermont Program Brings Long Trail Sixth, Seventh & Eighth Graders to Company’s Headquarters

From left, Long Trail seventh graders Savannah Petrossi and Ella Masker, along with Long Trail eighth grader Shaye Squillante, visit an assembly line during a visit to the Company’s headquarters in Arlington, Vt., Wednesday, Jan. 13, 2016.

ARLINGTON, Vt. (Jan. 20, 2016) – Mack Molding, a leading custom plastics molder and supplier of contract manufacturing services, recently opened its doors to give students from the Dorset, Vt.-based Long Trail School an inside look at running a business in the Green Mountain State.

“As a manufacturer, people are among the most important contributors to our success,” said Mack Molding President Jeff Somple, “and as a Vermont business, we recognize the importance of inspiring the state’s next generation of engineers, technicians and professionals. These students are the future of Vermont and its businesses, and through programs like our Made in Vermont Days, internships and school visits, Mack hopes to inform them of the exciting career paths right here at home.”

The students were participating in the Long Trail School’s own Made in Vermont program, in which sixth, seventh and eighth graders visited several regional businesses to gain an appreciation for how the businesses operate.

“We wanted students to see how local businesses take an idea from inception – that is identifying a problem or need – through design to the creation of a product to sales and marketing, and ultimately how it gets to the consumer,” said Long Trail’s Dean of Faculty Jim Gedney. “This was a great opportunity for experiential learning in which the students received outside of the classroom context through adults in the business world.”

According to Gedney, at the conclusion of the visits students executed on their new knowledge by coming up with prototype products and pitches in the spirit of ABC’s popular Shark Tank TV show. In all, students visited eight businesses for inspiration. In addition to Mack, other participants included Hubbardton Forge in Castleton, Vt.; Authentic Design in Rupert, Vt.; J.K. Adams in Dorset, Vt.; Orvis in Manchester, Vt.; Bennington Potters in Bennington, Vt.; Manchester Wood in Granville, N.Y.; and Battenkill Creamery in Salem, N.Y.

Long Trail School sixth grader Bryce Coe takes a bird’s-eye view of Mack Molding’s Finishing Department as students begin a tour of the Company’s headquarters in Arlington, Vt., Wednesday, Jan. 13, 2016.

“Middle school students are at a very open place for learning as they become more sophisticated in their understanding of things, moving from being concrete to analytical thinkers and learners,” Gedney added. “It means a lot to have the response we had from local companies at this critical time in their development, and we were impressed by their willingness to take time out of their busy schedules to host us. It shows a real interest in what the kids are learning in school and a real connection to the area – and the students come away with a better understanding of opportunities in the region.”

The Long Trail visit is just part of Mack’s longstanding commitment to encouraging Vermont’s best and brightest to use their talents to benefit the communities they call home, as well as the businesses that share them. The hallmark of Mack’s efforts is an internship program designed to have students work on meaningful projects that help move the business forward while giving them a significant achievement for their portfolios and resumes.

“We are quickly approaching 100 students who have been through the Mack internship program from schools like UVM, WPI, RPI and RIT,” Somple said. “We are now seeing some students return, which is truly rewarding not only because it validates our efforts, but because we see someone turn into a promising professional and hope we played our small part.”

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

About Long Trail School

Long Trail School is a coeducational, college preparatory day school located in Dorset, Vt. Founded in 1975, it serves 182 students in grades six through 12 from nearby towns in southwestern Vermont and New York state, as well as several countries. The school is approved by the Vermont State Board of Education, accredited by the New England Association of Schools and Colleges, and is authorized as an IB World School (#6248) by the International Baccalaureate Organization. For more information, visit www.longtrailschool.org.

Pictured, from left, are Long Trail School Director of College Consulting & Athletics Scott Magrath with students Bryce Coe, sixth grade; Savannah Petrossi, seventh grade; Ella Masker, seventh grade; Sophia Berumen, sixth grade; Shaye Squillante, eighth grade and Shayla Sisters, eighth grade; along with Mack Molding HQ Plant Manager Rich Hornby and Director of Human Resources Nancy Cefalo. Students toured the Company’s headquarters in Arlington, Vt., Wednesday, Jan. 13, 2016, to learn how business operate in the region as part of the school’s Made in Vermont program.

# # #